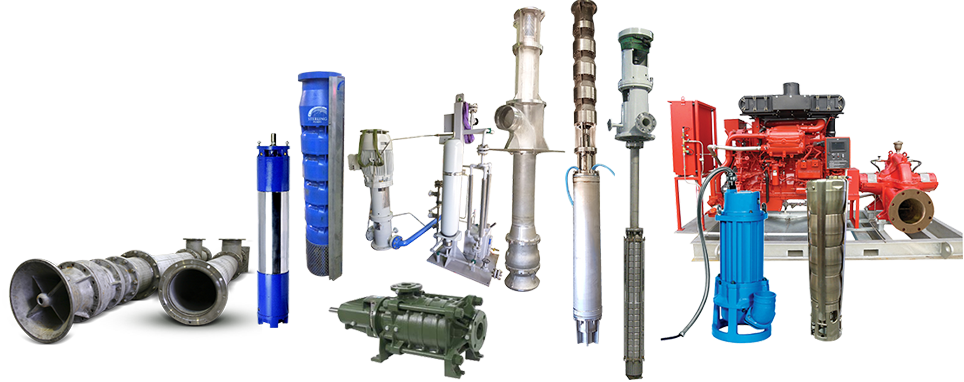

Products

Sterling Pumps is an Australian OEM (Original Equipment Manufacturer) who designs and manufactures a wide variety of pump products is both standard ranges and custom designs including Vertical Line Shaft Turbines, Submersible Turbines, Horizontal Multistage and Split case pumps, Submersible Borehole Motors and a wide range of spare parts.

We manufacture from a variety of high quality imported and local materials. Sterling products are carefully designed, manufactured and tested to International standards to give reliable and long service life being frequently installed in the largest and most crucial of industrial settings. The latest design and manufacturing techniques, including automated CNC machinery are used for maximum precision and shorter productions times. Our capabilities; see more…..

Standard Products

The Sterling Pumps broad range of standard ‘Commercial’ products are designed for usage that is common to many industries; Mining (Coal, Iron Ore, Nickel, Sand, Gold, Copper) Agriculture, Municipal, Oil/Gas, industrial, Fire Service and applications as diverse from stock watering, pit and mine de-watering, snow making, seawater lift on platform, crop irrigation and fire protection. These designs are frequently reassessed to ensure their usefulness to industry and are designed to be offered cost effectively.

Custom Design and Manufacture

Custom products are all uniquely designed to suit a client’s particular needs. We are able to provide solutions and advice on any pump-related need through the experience of our staff and our complete manufacturing capabilities. Sterling has an in-house design team who use the latest CAD and CAM software to develop products matching client needs. The manufacturing workshop can manufacture very large products for the most demanding of industry requirements.

Sterling Product Lines;

- Line Shaft Turbine pumps

- Submersible Turbine pumps

- Horizontal multistage pumps

- Pressed metal submersible borehole/well pumps

- Ballast pumps

- Inclined river/dam turbine pumps

- Booster style submersible pumps

- API 610 compliant pumps for oil and gas – onshore and offshore

- VS1, VS4, VS6 and OH2

- VS1 seawater lift and fire pump service

- VS6 for closed drain applications

- Condensate Extraction Pumps

- ESP seawater lift, closed and open drain pumps

- NFPA20 Fire Pumps and complete Fire Systems

- Split Case pumps

- Submersible Electric motors 0.55 kW to 600 kW, 415V to 11kV

- Drainage and Sewage pumps

- Vertical and horizontal dewatering pumps

- End Suction pumps

- Solids Handling pumps

Testing and Quality Control

Sterling Pumps has invested in our own in-house testing facility utilising both above ground tanks and a 15 metre deep wet well where all Sterling products are rigorously tested to ensure their dependability and suitability for their designed purpose. Under our ISO 9001 quality control manual, all material test certificates are recorded for the castings, forgings, pipes and bar stock.

Our testing facility can handle a variety of different pumps, from our Line shaft turbine pumps, submersible pumps to open drain pumps, split case, dewatering, fire pump packages and motor testing using a combination of world class equipment and decades of industry experience.

Aftersales Support

As the manufacturer, Sterling Pumps stocks a comprehensive range of spare parts for our pump products with the ability to produce discontinued or third party parts where needed. We offer pump repairs and servicing of our own pumps as well as competitors pumps in our fully capable repair workshop.

The aim of Sterling Pumps is to provide dependable and reliable pumps and motors that will work tirelessly for the purposes of our clients.