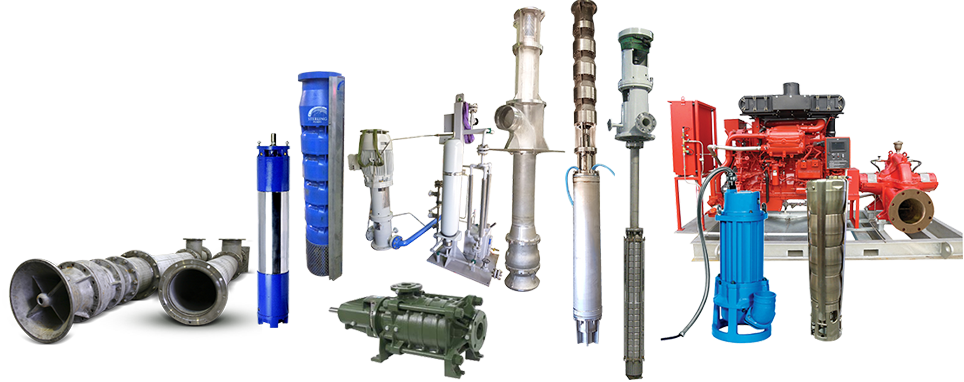

Turbine Submersible Pumps

TS Series

The Sterling Pumps TS series of Submersible Turbine Pumps are manufactured to be tough, offer corrosion resistant materials, delivering efficient and reliable operation across a broad range of pumping applications including town municipal water supply, irrigation and agricultural, mining, industrial, Oil and Gas applications, sea water lift, hydrocarbon transfer, pressure boosting and fire fighting applications.

Features & Options

- Standard sizes and flow rates available, 5” through to 12”, nominal 40 m³/h to 880 m³/h

- Larger sizes of 14”, 16” and 18” models are available for flows up to 1,100 m³/h

- Standard constructions materials: Cast Iron, Bronze, 316 stainless steel

- Additional construction materials available: Carbon Steel, Duplex Stainless Steel 2205, Super Duplex Stainless Steel 2507, Nickel Aluminium Bronze, Copper Nickel, Inconel 625, Ni Resist, Zeron 100

- Mixed flow impeller design

- Stacked impellers with separate shaft sleeves for long service life and ease of maintenance

- Stainless steel shafts

- Impeller materials” cast iron, bronze, stainless steel and to suit specific liquid being pumps

- Stainless steel cable guard

- Inlet strainer

- Check Valve to prevent back flow and minimise water hammer

- High efficiency design for water volume and energy use

- Motor mounting bracket conforms to NEMA standard for submersible motors

- Utilise standard NEMA submersible motors 0.55kW to 185kW and larger kW

- Second cable guard available for use with Star Delta 6 wire motors

- Standard BSP threaded outlet with NPT or flanged outlet available

- Water temperature 0°C up to 50°C

- Solids handling Maximum sand/solids in water; 50 g/m³

- Pump/motor Performance Based on 2,900 rpm, 2 pole 50 Hz and for larger sizes in 4 pole 50 Hz.

- Direction of rotation Clockwise as seen from the pump coupling side

- Pumps can be operated from diesel engine in case of fire

- Elastomers to suit liquid being pumped

- Comply with API610, NFPA20 and AS2941 fire standards

- Compact design for use in caisson for platform/offshore installations

- Available for Pressure Boosting applications, inline tube with minimal space and low noise emissions

- Available in Ballast Pump design, inverted motor in housing tube

- Custom design and build to your specifications

Specifications

TS = series

5 = nominal diameter inches

40 = nominal flow m³/h

5” TS series

Nominal flow ratings TS540 (m³/h)

Maximum flow up to 58 m³/h

Maximum head up to 230M

Discharge threads 3″ BSP

Motors up to 30 kW

6” TS series

Nominal flow ratings TS617, TS640, TS660, TS 685 (m³/h)

Maximum flow up to 78 m³/h

Maximum head up to 730M

Discharge threads 3” and 4” BSP

Motors up to 45 kW

7” TS series

Nominal flow ratings TS760, TS772, TS7100 (m³/h)

Maximum flow up to 180 m³/h

Maximum head up to 255M

Discharge threads 4” BSP

Motors up to 45 kW

8” TS series

Nominal flow ratings TS890, TS8150, TS8200, TS8230 (m³/h)

Maximum flow up to 280 m³/h

Maximum head up to 315M

Discharge threads 6” BSP

Motors up to 110 kW

10” TS series

Nominal flow ratings TS10250, TS10280, TS10350, TS10440, TS10550 (m³/h)

Maximum flow up to 680 m³/h

Maximum head up to 340M

Discharge threads 6” and 8” BSP

Motors up to 185 kW

12” TS series

Nominal flow ratings TS12650 (m³/h)

Maximum flow up to 880 m³/h

Maximum head up to 124M

Discharge threads 8” or 10” BSP

Motors up to 185 kW