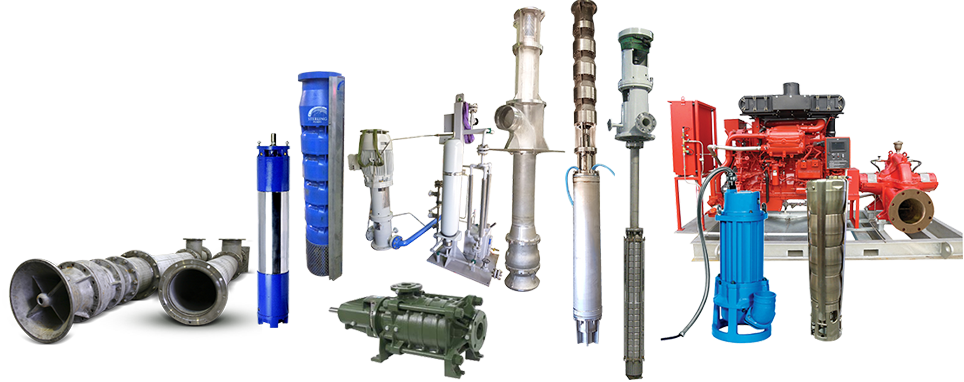

Line Shaft Turbines

Drive types: Electric motor or right angle gearbox/engine

VT Series

The Sterling Pumps VT, AX and MX series of Line Shaft Turbine Pumps are manufactured to be tough, offer corrosion resistant materials, delivering efficient and reliable operation across a broad range of pumping applications including town municipal water supply, irrigation and agricultural use, water transfer, mining, industrial, Oil and Gas applications, sea water lift, hydrocarbon transfer, pressure boosting and fire fighting applications.

Features & Options

- Standard sizes available, 5” 6″ 7″ 8″ 10″ 12″ 14″ 16″ 18″ 20″ 24″ with nominal flow up to 2,400 m³/h

- Sizes of 30″ through to 90″ models with flows up to 40,000 m³/h are available in various material specifications

- Standard constructions materials: Cast Iron, Zinc Free Bronze, 316 stainless steel

- Additional construction materials available: Carbon Steel, Duplex Stainless Steel 2205, Super Duplex Stainless Steel 2507, Nickel Aluminium Bronze, Copper Nickel, Inconel 625, Ni Resist, Zeron 100

- Mixed flow impeller design

- Our standard range also includes low lift/head and high volume;

- Axial Flow (AX series) aka Propeller Pumps 14″ to 20″+

- Mixed Flow (MX series) 8″ to 20″

- Stainless steel shafts as standard, Duplex available

- Fluted Resin NBR shaft bearings designed to pass particles and prolong service life on Water lubricated line shaft columns and bronze bearings for Oil lubricated line shaft columns.

- Impeller materials: cast iron, bronze or stainless steel and to suit specific liquid being pumps

- All impellers can be trimmed to suit your specific duty

- Inlet strainer, various designs available

- High efficiency design for water volume and energy use

- Flanged outlet to column, can be threaded BSP or NPT or other

- Water temperature 0°C up to 50°C

- Solids handling Maximum sand/solids in water; 50 g/m³

- Performance based on 2 and 4 pole 50 Hz IEC motors or diesel engine via gearbox drive, refer Performance Curves

- Pumps can be operated from direct drive electric motor or via angle drive gearbox coupled to diesel engine

- Elastomers to suit liquid being pumped

- Comply with API610 and NFPA 20 fire standards

- Complaint for Oil and Gas API610 Vertically Suspended (VS) pump applications

- Mild steel and 304SS columns standard, 3 metre lengths, Water or Oil lubricated, flanged or threaded connections

- Rubber, mild steel or stainless steel centralizers (aka stabilizers/spiders) for Oil Lubricated columns. Other materials to match the pump construction available.

- W series 304SS and 316SS fabricated pump ends can also be manufactured as Line Shaft ‘WT series’ pumps.

- Custom design and build to your specifications

If we do not have the right Line Shaft Turbine pump model for your application, we can easily custom design one to meet your material and flow requirements. Please use the ‘Contact Us’ form or phone us.

Specifications

VT (AX-MX) = series number

5 = nominal diameter inches

A = 1st impeller trim

A = 2nd impeller trim

Q = max. flow. H = max. head

2900 rpm = electric 2 pole 50hz

1450 rpm = electric 4 pole 50hz

1500 to 2300 rpm = diesel range

5BA: Q; 58m³/h, H; 200M

6CA: Q; 100m³/h, H; 136M

6DA: Q; 85m³/h, H; 128M

7AA: Q; 84m³/h, H; 207M

7CA: Q; 180m³/h, H; 260M

8AA: Q; 300m³/h, H; 202M

8BA: Q: 280m³/h, H: 160M

8CA: Q; 128m³/h, H; 234M

8DA: Q; 142m³/h, H; 255M

8DB: Q; 132m³/h, H; 248M

8EA: Q; 250m³/h, H; 88M

8GA: Q; 136m³/h, H; 188M

8HA: Q; 195m³/h, H; 174M

10AA: Q; 295m³/h, H; 272M

10BA: Q; 405m³/h, H; 245M

10CA: Q; 495m³/h, H; 218M

10GA: Q; 225m³/h, H; 310M

10HA: Q; 245m³/h, H; 368M

10JA: Q; 240m³/h, H; 288M

10KA: Q; 385m³/h, H; 270M

10LA: Q: 700m³/h, H: 265M

10LB: Q:480m³/h, H: 240M

12AA 1450: Q; 295m³/h, H; 168M

12AA 1750: Q; 350m³/h, H; 138M

12BA 1450: Q; 450m³/h, H; 125M

12BA 1750: Q; 540m³/h, H; 112M

12BA 2900: Q; 880m³/h, H; 184M

12CA 1450: Q; 520m³/h, H; 92M

12CA 1750: Q; 620m³/h, H; 110M

14AA 1450: Q; 690m³/h, H; 114M

14AA 1750: Q; 830m³/h, H; 133M

14BA 1450: Q; 1020m³/h, H; 162M

14BA 1750: Q; 1200m³/h, H; 224M

16AA 1450: Q; 900m³/h, H; 272M

16AA 1750: Q; 1035m³/h, H; 485M

18AA 1450: Q; 1160m³/h, H; 203M

18AA 1750: Q; 1390m³/h, H; 229M

18BA 1450: Q; 1085m³/h, H; 102M

18BA 1750: Q; 1300m³/h, H; 97M

18CA 1450: Q; 1280m³/h, H; 207M

18CA 1750: Q; 1500m³/h, H; 172M